Metallic Red Inspiration: The Enclosed Drone Introduction:Embark on a journey into the future of drone training with a creation commissioned by our esteemed client. This enclosed training drone, a marvel conceived by Project Faction, redefines safety, aesthetics, and functionality in the realm of unmanned aerial vehicles. From its glass fiber shell to the metallic red allure, let’s explore the intricacies of this eye-catching innovation. The Protective Enclosure:At the core of this innovation is the meticulously designed glass fiber shell that serves as both fenders and a protective enclosure for all electronic components. This forward-thinking approach not only enhances safety during training sessions but also introduces a new level of durability to withstand inadvertent collisions. The motors, featuring ducted designs, find shelter within the robust glass fiber shell. Aesthetic Brilliance in Metallic Red:As the drone takes to the skies, its metallic red exterior with sparkling accents becomes an instant visual spectacle. The vibrant hue not only adds a touch of elegance but also ensures that the drone remains easily visible during flight. This striking design not only fulfills functional requirements but also turns heads with its captivating appearance. Carbon Fiber Plates for Structural Excellence:Ensuring a balance of strength and lightweight construction, the bottom plate of the drone is crafted from high-quality carbon fiber. This choice of material not only contributes to the drone’s structural integrity but also complements the overall aesthetic, creating a harmonious blend of form and function. Precision Printing and Finishing:The intricate holders and smaller parts essential for the drone’s assembly are meticulously 3D printed by Project Faction. The team takes pride in achieving precision in every detail. Following the printing process, each part undergoes thorough sanding and finishing, ensuring a flawless surface and impeccable quality. Mold Mastery by Project Faction:The crowning achievement in the creation of this enclosed training drone lies in the development of the mold for casting the glass fiber shell. Project Faction’s expertise shines through in the innovative mold design, a key element that enables the creation of the protective enclosure. This mastery demonstrates the team’s dedication to pushing the boundaries of drone design. Grateful for the Opportunity:The creation of this enclosed training drone is not just a project; it’s an opportunity to showcase our passion for innovation and commitment to excellence. Project Faction is grateful for the chance to bring this groundbreaking concept to life and contribute to the evolution of drone technology. Conclusion:As the enclosed training drone takes flight, it symbolizes a leap forward in safety, design, and functionality. This metallic red marvel, commissioned by our client and brought to life by Project Faction, stands as a testament to the limitless possibilities that arise when innovation and expertise converge. With every ascent, this drone paves the way for a future where training drones seamlessly marry protection with visual allure in the vast skies of technological progress.

Carbon Fibre Motor mounts – Drones

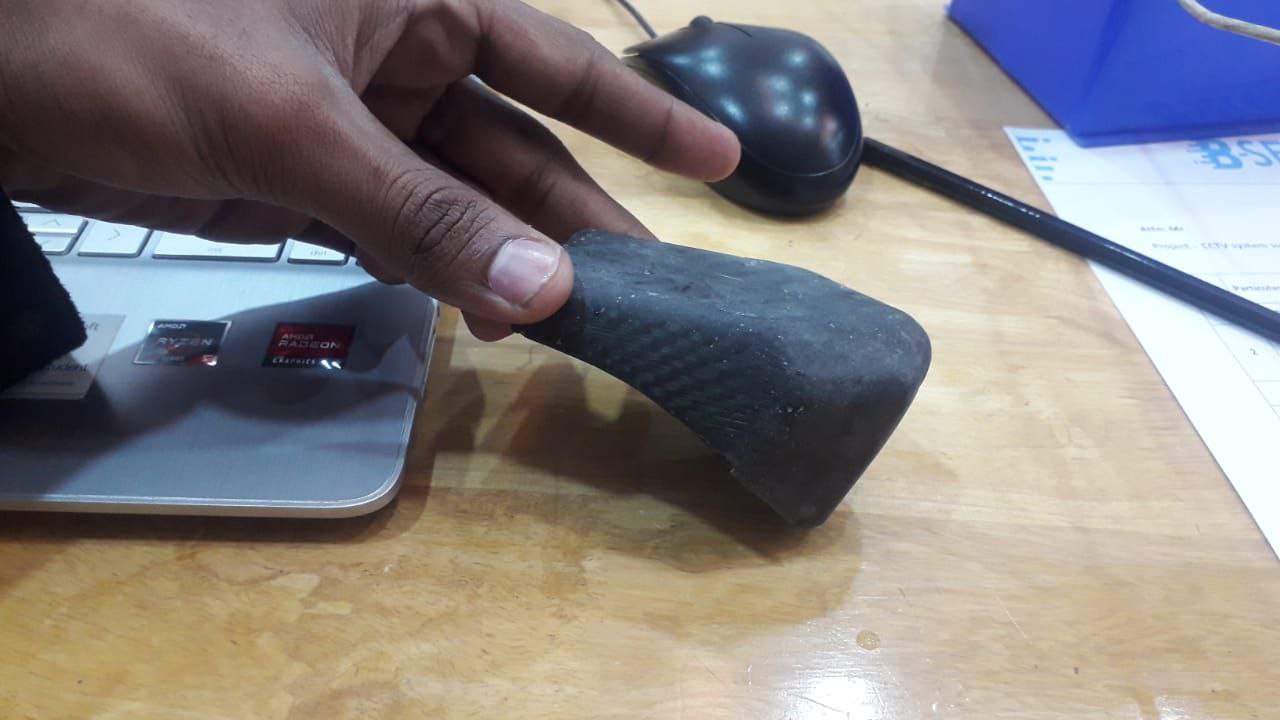

Revolutionizing Design with Custom Carbon Fiber Mounts Introduction:Embarking on a journey of innovation, Project Faction introduces a groundbreaking solution to the world of design — custom carbon fiber mounts. Weighing between 10 to 12 grams, these mounts redefine the possibilities of engineering, providing a perfect blend of strength and versatility. Engineering Excellence:Crafted through a meticulous process of compressing chopped carbon fiber strands mixed with resins in multi-part 3D-printed molds, these mounts have been designed to withstand normal loads up to 15 kg. The result is a material that boasts an exceptional strength-to-weight ratio, allowing for the creation of complex shapes with reduced weight compared to traditional aluminum counterparts. Technical Specifications and Ratios:This innovative approach to mount creation extends beyond conventional limits. The technical prowess lies in achieving a high strength-to-weight ratio, enabling engineers to produce mounts that are not only robust but also significantly lighter than their aluminum counterparts. This ratio ensures optimal performance without compromising structural integrity. Sustainability and Cost-Effectiveness:A standout feature of these mounts is their sustainability. The 3D-printed molds, ingeniously designed, are reusable multiple times when handled with care. This not only reduces production costs but also aligns with a sustainable approach to engineering, making custom carbon fiber parts an economically viable and environmentally conscious solution. Innovative Design Process:The engineers at Project Faction have played a pivotal role in the creation of these custom mounts. Spearheading the research and development of this novel methodology, Project Faction has achieved outstanding results, demonstrating that cutting-edge design and high-performance materials can be both accessible and cost-effective. Conclusion:As we introduce custom carbon fiber mounts to the world, the innovation of Project Faction becomes evident. Striking a balance between strength, weight, and cost-effectiveness, these mounts represent a leap forward in materials science. The future of design is here, and it’s marked by lightweight, durable, and tailor-made solutions that transcend industry standards.

Tortoise the Tri-Copter

Introducing “Tortoise”: A Quirky 3D-Printed Tricopter by The Designer and UDT Design Community Introduction:In the world of drone technology, Project Faction introduces “Tortoise,” a tricopter with a unique touch. Designed by “The Designer” in collaboration with UDT Design Community intern Vijaykrishna PV in 2019, this 3D-printed creation combines simplicity with a subtle nod to tortoise aesthetics. The Birth of “Tortoise”:“The Designer” and Vijaykrishna PV joined forces, utilizing Project Faction’s 3D printing capabilities to bring “Tortoise” to life. The tricopter features a distinctive shell design that hints at a tortoise’s appearance while maintaining a sleek and modern look. Eyes that Come to Life:One notable feature of “Tortoise” is its glowing eyes, which come to life during arming. This small touch adds a hint of personality to the tricopter, setting it apart from standard drones. Technical Specifications:The tricopter is equipped with a Pixhawk flight controller, and the team conducted PID tuning to ensure stability during flight, preventing any unwanted tail wagging. The result is a smooth and controlled flying experience. “Tortoise” boasts arms made from carbon fiber tubes, striking a balance between lightweight construction and structural strength. With a weight of around 1.2 kg, the tricopter is agile and nimble in various environments. Featuring A2212 BLDC motors, 30A SimonK ESCs, and 9-inch props, “Tortoise” is designed for a harmonious blend of power and efficiency. The 3S 1000mAh LiPo battery provides a reliable power source for extended flight times. Conclusion:“Tortoise” may not be a groundbreaking project, but it stands as a testament to the collaborative efforts of The Designer and Vijaykrishna PV. This 3D-printed tricopter merges innovative design with practical technology, challenging traditional drone norms. As we unveil “Tortoise” to the world, we invite enthusiasts to appreciate the simplicity and creativity behind this quirky creation. What other wonders might be in the minds of The Designer and the UDT Design Community? The journey of exploration continues, and “Tortoise” represents a small step into a future where drones are not just machines but also expressions of creative ingenuity. https://projectfaction.com/wp-content/uploads/2021/03/video_2024-02-09_23-03-10.mp4