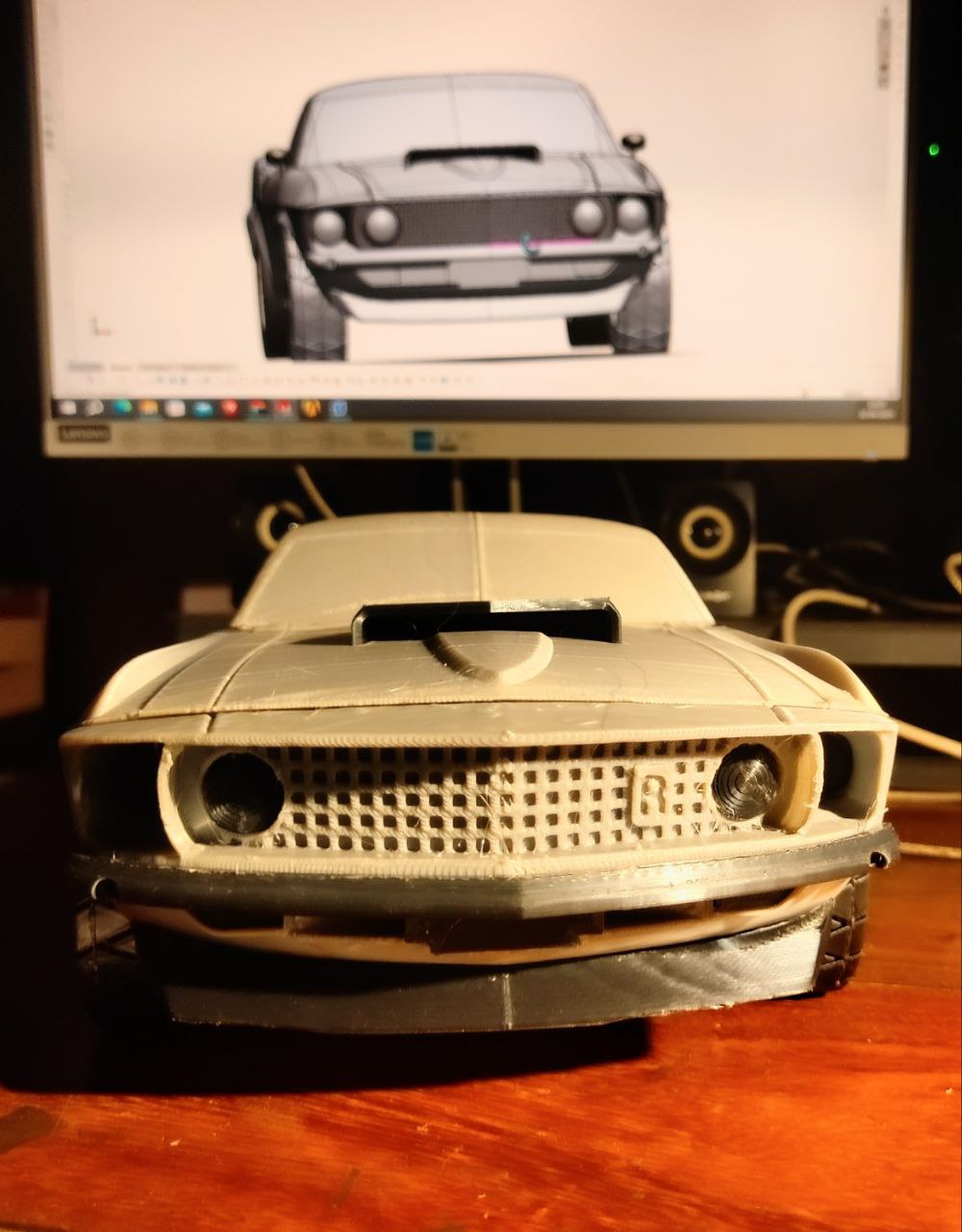

Designing the Boss 429 Ford Mustang Introduction: Embark on a journey to resurrect automotive history as we delve into the meticulous process of creating a scaled 3D model of the legendary Boss 429 Ford Mustang. Designed by The Designer at Project Faction, this project marks a pioneering effort in automotive design and digital restoration. Join us as we explore the intricacies of CAD technology and 3D printing in bringing this iconic vehicle back to life in a new dimension. Scaled 3D Model Creation: The project commenced with The Designer at Project Faction dedicating nearly 60 hours to meticulously craft surface models of the Boss 429 Ford Mustang. These intricate models serve as the blueprint for the scaled 3D model, capturing every detail and contour of the original vehicle. Converting the surface model into a 3D printable solid model required an additional 20 hours of precision work to ensure accuracy and fidelity to the original design. Printing Process: With the solid model finalized, the printing process commenced, a feat that consumed almost 250 hours in total. Leveraging two FDM printers working around the clock, piece by piece, the parts slowly took shape over the course of a week. This methodical approach ensured that each component was crafted with care and attention to detail, maintaining the integrity of the original design. Technological Advancements: While FDM printing proved effective for this project, it’s worth noting that resin printers offer an alternative solution for achieving high-resolution parts with exceptional finish. The evolution of 3D printing technology continues to revolutionize the digital restoration process, offering new possibilities for recreating automotive masterpieces with unparalleled precision. Stay tuned for the unveiling of our scaled 3D model, a testament to the power of technology in preserving automotive heritage and re-imagining classic vehicles for the digital age.

Unveiling the Titan: The Heavy Lift Quadcopter

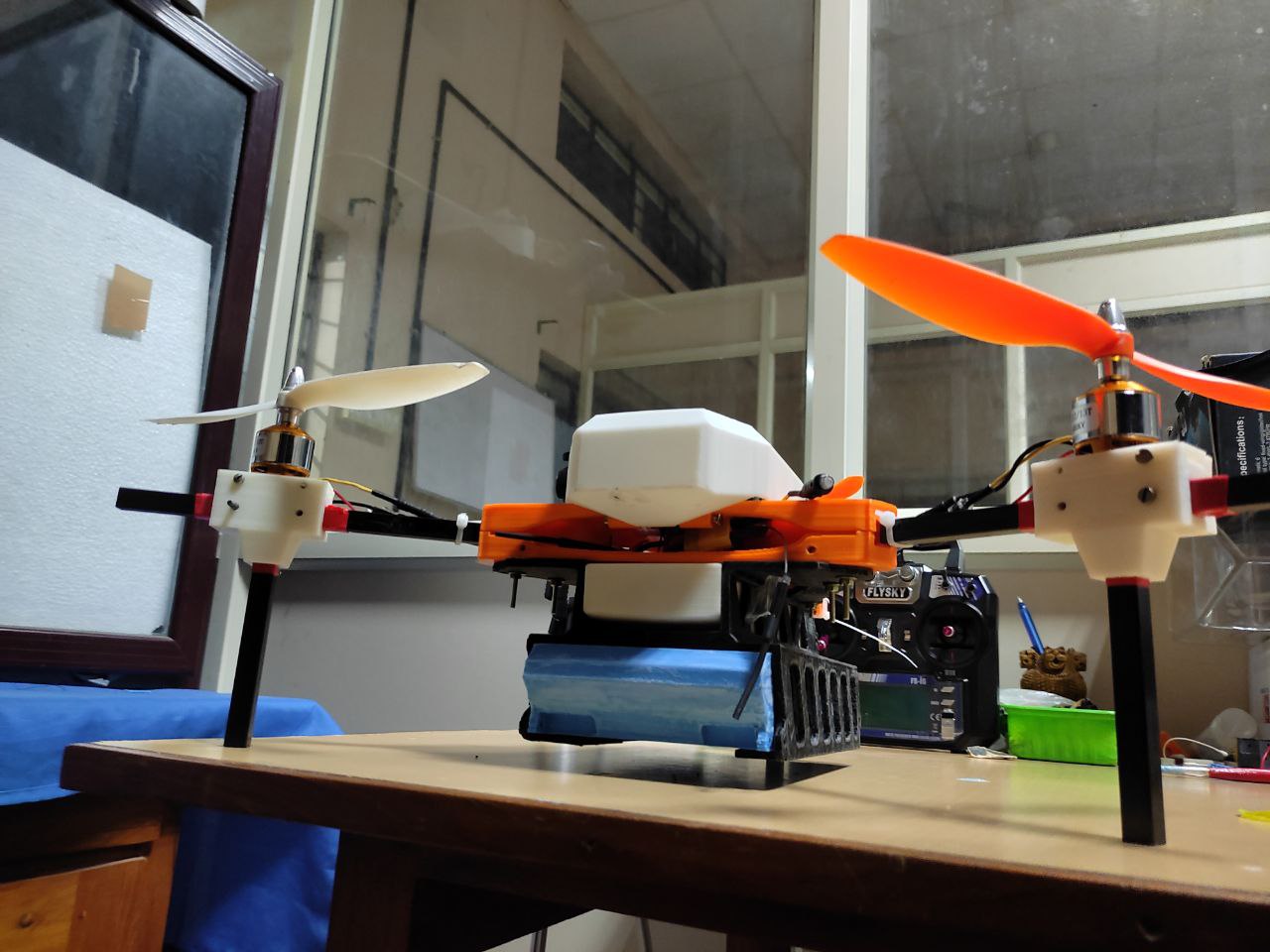

Unveiling the Titan: The Heavy Lift Quadcopter Introduction:Step into the world of heavy lift capabilities with our latest creation – a quadcopter that pushes the boundaries of aerial performance. While specific specs remain confidential due to client discretion, the essence lies in its unique design, conceptualized by the visionary “Designer” and brought to life by the skilled hands of Vijaykrishna PV, an intern from the UDT Design Community. This heavy lift quadcopter not only boasts impressive capabilities but also features a design that exudes both calmness and menace. Let’s delve into the intricacies of this powerful aerial marvel. The Designer’s Vision:At the heart of this heavy lift quadcopter is the visionary design crafted by “The Designer”. The undisclosed specifications add an air of mystery, making it a testament to cutting-edge technology. The quadcopter is not just a drone; it’s a manifestation of engineering prowess and a commitment to pushing the boundaries of aerial capabilities. Vijaykrishna PV’s Craftsmanship:Brought to life by Vijaykrishna PV, an intern from the UDT Design Community, this heavy lift quadcopter stands as a testament to the collaborative spirit and innovation within our team. Vijaykrishna’s craftsmanship transforms concepts into reality, with a keen focus on achieving both a calm aesthetic and a hint of menace in the design. 3D Printed Shell and Carbon Fiber Frame:The exterior of the quadcopter features a 3D printed shell, adding not only a sleek finish but also ensuring optimal aerodynamics. The choice of materials contributes to the overall lightweight construction, a critical factor in achieving the heavy lift capabilities required. The carbon fiber frame, known for its strength and durability, serves as the backbone, providing structural integrity to support the quadcopter’s robust functionality. Calm Yet Menacing Aesthetics:In the world of heavy lift drones, aesthetics matter. This quadcopter strikes a balance between a calm exterior and a menacing presence. The design elements not only enhance its visual appeal but also convey a sense of authority, emphasizing the power it holds within. Conclusion:The unveiling of this heavy lift quadcopter marks a significant milestone in our journey at UDT. With an enigmatic design, crafted by “The Designer” and brought to life by the hands of Vijaykrishna PV, it stands as a symbol of innovation and expertise. While we respect client confidentiality regarding the detailed specifications, the essence of this creation lies in its unique design and unparalleled heavy lift capabilities. As we soar into the future, one can’t help but wonder what other marvels await in the skies of UDT’s imagination.

Mad Max Design- Remote Controller

MAD MAX DESIGN- REMOTE CONTROLLER Project Faction’s Mad Max-inspired Remote Controller Unveiled Introduction:In the imaginative landscapes where survival is a daily challenge, emerges a collaborative masterpiece by the visionary designers of Project Faction and interns from the UDT Design Community. This remote controller transcends conventional boundaries, offering a glimpse into a post-apocalyptic realm. The Birth of an Idea:At the core of this innovation is the brainchild of Project Faction’s enigmatic designer, known simply as “The Designer,” drawing inspiration from the chaotic world of Mad Max. The goal was to create a remote controller seamlessly integrated into the harsh landscapes of a post-apocalyptic future. The Collaborative Force:The remote controller’s design came to life through The Designer and the collaborative efforts of Aswin PK, Chris Jose Panicker, and Athulya S Ramesh—talented interns from the UDT Design Community. Together, they conceptualized, designed, and crafted a three-piece, 3D-printed marvel that defies convention. The Structure:Crafted with sharp contours, the three floating parts are seamlessly connected using lightweight carbon fiber tubes. The design is a testament to technical prowess and a dedication to pushing boundaries. Illuminating Power:The green illuminated power button commands attention, adding a touch of mystique to the controller. This subtle yet powerful feature invites users into a universe of possibilities. Control in Your Hands:A needle/toggle switch, reminiscent of a survivalist’s toolkit, allows users to navigate controls effortlessly. Tactile feedback and precise functionality make this remote controller an extension of oneself—a companion in harsh terrains. A Palette of Resilience: The metallic orange of the end pieces and metallic grey of the central part reflect the toughness required in a post-apocalyptic world. Conclusion:Project Faction’s Mad Max-inspired remote controller stands as a testament to the potential when visionary designers and aspiring talents unite. Shrouded in mystery, this creation is not merely a controller; it symbolizes survival, innovation, and the unyielding spirit of humanity. As we unveil this masterpiece, one wonders: What other secrets lie in the shadows of Project Faction’s imagination? The answer, like the identity of its creator, remains a tantalizing mystery waiting to be unraveled.

Unveiling the Vermillion – Unique Quadcopter

Unveiling the Vermilion: A Symphony of Innovation and Aesthetics in H-Configuration Introduction:In the realm of drone design, a new marvel takes flight with the Vermillion. This groundbreaking project, spearheaded by interns from the UDT Mechanical Design Program’s 2022-23 batch, showcases a blend of visionary design conceptualized by “The Designer” at Project Faction and the collaborative efforts of Aswin PK, Chris Jose Panicker, and Athulya Ramesh. As we delve into the intricacies of this drone, we uncover a symphony of innovation and aesthetics. The Conceptualization:“The Designer” at Project Faction envisioned a drone that not only defied conventional design norms but also stood out as a piece of art in the sky. The UDT interns, Aswin PK, Chris Jose Panicker, and Athulya Ramesh, played a crucial role in translating this vision into reality by 3D modeling the chassis and interior structures, giving life to a unique concept that seamlessly blends form and function. Unique Shell Design:The Vermilion boasts a distinctive 3-piece shell design. The main shell encloses the flight controller, while two fender-like shells on either side house the ESCs of the motors. This design not only adds to its aesthetic appeal but also serves a functional purpose. The ESC compartments are strategically designed to collect airflow during flight, regulating the temperature and ensuring operational efficiency. Carbon Fiber Components:Continuing the tradition of innovation from Project Faction, the Vermilion incorporates motor mounts made from carbon fibers, as introduced in the previous blog on custom carbon fiber mounts. This not only enhances the drone’s structural integrity but also significantly reduces weight, contributing to its overall agility and performance. H-Shaped Chassis Configuration:The chassis of the Vermilion adopts an H-shaped configuration, providing stability and balance during flight. Carbon fiber tubes serve as the arms, ensuring a lightweight yet robust structure. The Pixhawk flight controller orchestrates the drone’s movements, while A2212 BLDC motors, 40A ESCs, and a 3S LiPo 1500mAh battery power its flight. Innovation in Action:Printed at Project Faction, the Vermilion weighs in at 1.5 kg, a testament to the team’s dedication to advanced technologies in an affordable manner. The drone has not only won accolades at various college events but also stole the spotlight at Ente Keralam 2023, captivating the audience and sparking inquiries from enthusiasts eager to own this innovative design. Conclusion:The Vermilion stands as more than just a drone; it is a testament to the collaborative spirit of the UDT Mechanical Design Program interns and the visionary design of “The Designer” at Project Faction. As it gracefully soars through the skies, this drone represents a harmonious convergence of cutting-edge technology and artistic design.

Multi-Mission Tri-Copter

Unleashing Versatility: The Multi-Mission Tricopter from Sivaji College of Engineering and Technology Introduction:In the innovative landscape of drone design, a new multi-mission capable tricopter emerges as a testament to creativity and functionality. This proof-of-concept marvel, crafted by students Anoop A.P., Muhammad Faizal A, Karthikdeep J. and Bijil A.B., Mechanical Engineering undergraduates (2019-23) from Sivaji College of Engineering and Technology in Nayyatinkara, Trivandrum, Kerala, pushes the boundaries of aerial capabilities. Let’s unravel the story of this rugged yet versatile tricopter, a smaller version designed for a specific project but leaving a lasting impact. The Design Genesis:At the heart of this aerial innovation lies the vision of “The Designer” at Project Faction. This visionary conceptualized a tricopter that goes beyond conventional limits, offering a glimpse into the future of aerial missions. The project, executed by students from Sivaji College of Engineering and Technology, is a fusion of rugged aesthetics and multi-mission functionality. Versatility in Payload:What sets this tricopter apart is its multi-mission capability. The payload bay serves as a versatile platform, accommodating various accessories such as floodlights, public announcement systems, and even a package dropping mechanism. This adaptability opens doors to a myriad of applications, from search and rescue missions to surveillance and public events. Rugged Aesthetics:Despite its proof-of-concept nature, the tricopter doesn’t compromise on aesthetics. The rugged design not only adds a touch of resilience but also reflects the dedication of the students in crafting a drone that can withstand various operational challenges. The combination of carbon fiber tubes for the arms and a 3D-printed frame contributes to both durability and lightweight construction. Technical Specifications: – Flight Controller: Pixhawk– ESCs: 40A– Motors: A2212– Frame: 3D printed– Arms: Carbon fiber tubes– Propellers: 9-inch– Weight (without payload): 1.2 kg– Payload Weight Capacity: 300 grams– Battery: 2200mAh LiPo Academic Prowess from Sivaji College:This tricopter project proudly represents the ingenuity of students from Sivaji College of Engineering and Technology. Their dedication to pushing the boundaries of drone technology for a specific project showcases the innovative spirit cultivated within the college. Conclusion:As we witness the unveiling of the multi-mission tricopter from Sivaji College of Engineering and Technology, we’re reminded of the boundless possibilities that lie ahead in the realm of drone design. This proof-of-concept marvel, conceptualized by “The Designer” at Project Faction, not only showcases technical prowess but also highlights the collaborative efforts of aspiring engineers in Trivandrum, Kerala. This tricopter stands as a testament to the limitless potential of aerial missions, even in its smaller, project-specific form.

Tortoise the Tri-Copter

Introducing “Tortoise”: A Quirky 3D-Printed Tricopter by The Designer and UDT Design Community Introduction:In the world of drone technology, Project Faction introduces “Tortoise,” a tricopter with a unique touch. Designed by “The Designer” in collaboration with UDT Design Community intern Vijaykrishna PV in 2019, this 3D-printed creation combines simplicity with a subtle nod to tortoise aesthetics. The Birth of “Tortoise”:“The Designer” and Vijaykrishna PV joined forces, utilizing Project Faction’s 3D printing capabilities to bring “Tortoise” to life. The tricopter features a distinctive shell design that hints at a tortoise’s appearance while maintaining a sleek and modern look. Eyes that Come to Life:One notable feature of “Tortoise” is its glowing eyes, which come to life during arming. This small touch adds a hint of personality to the tricopter, setting it apart from standard drones. Technical Specifications:The tricopter is equipped with a Pixhawk flight controller, and the team conducted PID tuning to ensure stability during flight, preventing any unwanted tail wagging. The result is a smooth and controlled flying experience. “Tortoise” boasts arms made from carbon fiber tubes, striking a balance between lightweight construction and structural strength. With a weight of around 1.2 kg, the tricopter is agile and nimble in various environments. Featuring A2212 BLDC motors, 30A SimonK ESCs, and 9-inch props, “Tortoise” is designed for a harmonious blend of power and efficiency. The 3S 1000mAh LiPo battery provides a reliable power source for extended flight times. Conclusion:“Tortoise” may not be a groundbreaking project, but it stands as a testament to the collaborative efforts of The Designer and Vijaykrishna PV. This 3D-printed tricopter merges innovative design with practical technology, challenging traditional drone norms. As we unveil “Tortoise” to the world, we invite enthusiasts to appreciate the simplicity and creativity behind this quirky creation. What other wonders might be in the minds of The Designer and the UDT Design Community? The journey of exploration continues, and “Tortoise” represents a small step into a future where drones are not just machines but also expressions of creative ingenuity. https://projectfaction.com/wp-content/uploads/2021/03/video_2024-02-09_23-03-10.mp4

The First Tri-Copter

First Tricopter: A Journey into 3D-Printed Innovation Introduction:In 2019, the UDT CAD Course, now known as the UDT Mechanical Design Program, witnessed a transformative moment. Project Faction, a pioneer in technological exploration, marked a significant milestone by 3D printing the first tricopter. This groundbreaking project not only showcased the potential of 3D printing but also set the stage for future innovations within the program. The Genesis of the Tricopter:Conceived as part of the UDT CAD Course, the tricopter emerged as a testament to the program’s commitment to pushing boundaries. The initial design, crafted by Project Faction, laid the foundation for becoming a symbol of innovation within the UDT Mechanical Design Program. Unique Shell Design:The tricopter’s defining feature is its distinctive shell design, capturing attention with its unconventional aesthetic. This unique characteristic adds a touch of creativity and serves as a representation of the program’s dedication to fostering innovative design solutions. Carbon Fiber Arms and 3D-Printed Chassis:Crafted with long, slender arms made from carbon fiber, the tricopter’s structural integrity is enhanced while maintaining a lightweight profile. The entire chassis or frame is fully 3D printed, showcasing the program’s commitment to embracing modern manufacturing techniques. A Glimpse into the Future:The 2019 tricopter project serves as a precursor to the future of design education within the UDT Mechanical Design Program. By combining traditional principles with cutting-edge technologies like 3D printing, students are encouraged to think beyond conventional boundaries and pioneer new realms of design. Technical Specifications:The tricopter is equipped with a Pixhawk flight controller, 30A SimonK ESCs, and A2212 motors, all contributing to its stability and precise aerial maneuvers. With long, slender carbon fiber arms and a fully 3D-printed chassis, this tricopter exemplifies the program’s dedication to merging innovative design and advanced manufacturing techniques. Conclusion:As we reflect on the first tricopter born from the UDT CAD Course in 2019, now an integral part of the UDT Mechanical Design Program, we see more than a mere drone. It represents the spirit of innovation, the fusion of traditional and modern design principles, and a commitment to pushing the limits of what’s possible. The journey has just begun, and with each new project, the UDT Mechanical Design Program continues to shape the future of design education. https://projectfaction.com/wp-content/uploads/2021/12/tricopter-first.mp4