Unleashing Versatility: The Multi-Mission Tricopter from Sivaji College of Engineering and Technology Introduction:In the innovative landscape of drone design, a new multi-mission capable tricopter emerges as a testament to creativity and functionality. This proof-of-concept marvel, crafted by students Anoop A.P., Muhammad Faizal A, Karthikdeep J. and Bijil A.B., Mechanical Engineering undergraduates (2019-23) from Sivaji College of Engineering and Technology in Nayyatinkara, Trivandrum, Kerala, pushes the boundaries of aerial capabilities. Let’s unravel the story of this rugged yet versatile tricopter, a smaller version designed for a specific project but leaving a lasting impact. The Design Genesis:At the heart of this aerial innovation lies the vision of “The Designer” at Project Faction. This visionary conceptualized a tricopter that goes beyond conventional limits, offering a glimpse into the future of aerial missions. The project, executed by students from Sivaji College of Engineering and Technology, is a fusion of rugged aesthetics and multi-mission functionality. Versatility in Payload:What sets this tricopter apart is its multi-mission capability. The payload bay serves as a versatile platform, accommodating various accessories such as floodlights, public announcement systems, and even a package dropping mechanism. This adaptability opens doors to a myriad of applications, from search and rescue missions to surveillance and public events. Rugged Aesthetics:Despite its proof-of-concept nature, the tricopter doesn’t compromise on aesthetics. The rugged design not only adds a touch of resilience but also reflects the dedication of the students in crafting a drone that can withstand various operational challenges. The combination of carbon fiber tubes for the arms and a 3D-printed frame contributes to both durability and lightweight construction. Technical Specifications: – Flight Controller: Pixhawk– ESCs: 40A– Motors: A2212– Frame: 3D printed– Arms: Carbon fiber tubes– Propellers: 9-inch– Weight (without payload): 1.2 kg– Payload Weight Capacity: 300 grams– Battery: 2200mAh LiPo Academic Prowess from Sivaji College:This tricopter project proudly represents the ingenuity of students from Sivaji College of Engineering and Technology. Their dedication to pushing the boundaries of drone technology for a specific project showcases the innovative spirit cultivated within the college. Conclusion:As we witness the unveiling of the multi-mission tricopter from Sivaji College of Engineering and Technology, we’re reminded of the boundless possibilities that lie ahead in the realm of drone design. This proof-of-concept marvel, conceptualized by “The Designer” at Project Faction, not only showcases technical prowess but also highlights the collaborative efforts of aspiring engineers in Trivandrum, Kerala. This tricopter stands as a testament to the limitless potential of aerial missions, even in its smaller, project-specific form.

Tortoise the Tri-Copter

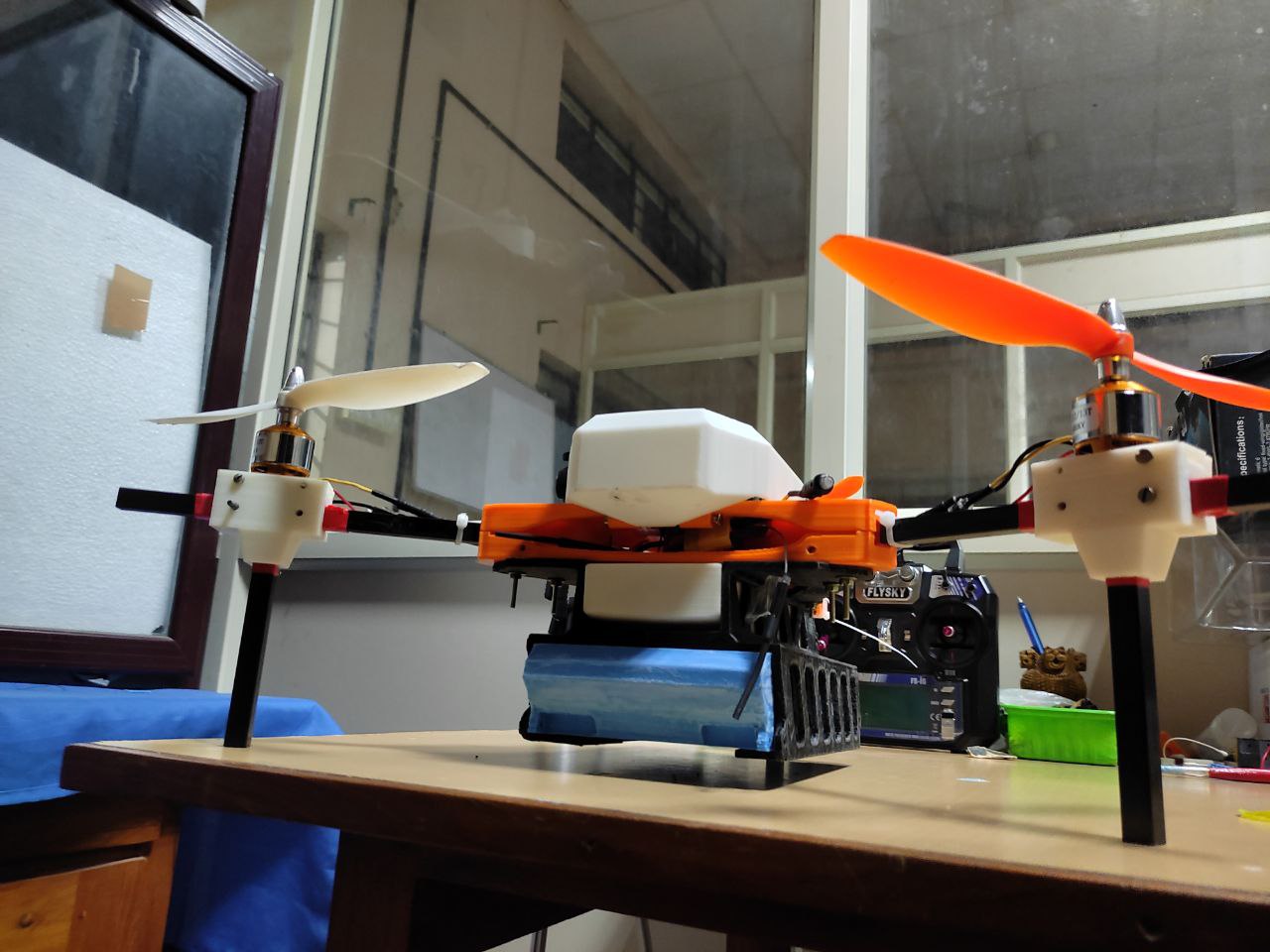

Introducing “Tortoise”: A Quirky 3D-Printed Tricopter by The Designer and UDT Design Community Introduction:In the world of drone technology, Project Faction introduces “Tortoise,” a tricopter with a unique touch. Designed by “The Designer” in collaboration with UDT Design Community intern Vijaykrishna PV in 2019, this 3D-printed creation combines simplicity with a subtle nod to tortoise aesthetics. The Birth of “Tortoise”:“The Designer” and Vijaykrishna PV joined forces, utilizing Project Faction’s 3D printing capabilities to bring “Tortoise” to life. The tricopter features a distinctive shell design that hints at a tortoise’s appearance while maintaining a sleek and modern look. Eyes that Come to Life:One notable feature of “Tortoise” is its glowing eyes, which come to life during arming. This small touch adds a hint of personality to the tricopter, setting it apart from standard drones. Technical Specifications:The tricopter is equipped with a Pixhawk flight controller, and the team conducted PID tuning to ensure stability during flight, preventing any unwanted tail wagging. The result is a smooth and controlled flying experience. “Tortoise” boasts arms made from carbon fiber tubes, striking a balance between lightweight construction and structural strength. With a weight of around 1.2 kg, the tricopter is agile and nimble in various environments. Featuring A2212 BLDC motors, 30A SimonK ESCs, and 9-inch props, “Tortoise” is designed for a harmonious blend of power and efficiency. The 3S 1000mAh LiPo battery provides a reliable power source for extended flight times. Conclusion:“Tortoise” may not be a groundbreaking project, but it stands as a testament to the collaborative efforts of The Designer and Vijaykrishna PV. This 3D-printed tricopter merges innovative design with practical technology, challenging traditional drone norms. As we unveil “Tortoise” to the world, we invite enthusiasts to appreciate the simplicity and creativity behind this quirky creation. What other wonders might be in the minds of The Designer and the UDT Design Community? The journey of exploration continues, and “Tortoise” represents a small step into a future where drones are not just machines but also expressions of creative ingenuity. https://projectfaction.com/wp-content/uploads/2021/03/video_2024-02-09_23-03-10.mp4

The First Tri-Copter

First Tricopter: A Journey into 3D-Printed Innovation Introduction:In 2019, the UDT CAD Course, now known as the UDT Mechanical Design Program, witnessed a transformative moment. Project Faction, a pioneer in technological exploration, marked a significant milestone by 3D printing the first tricopter. This groundbreaking project not only showcased the potential of 3D printing but also set the stage for future innovations within the program. The Genesis of the Tricopter:Conceived as part of the UDT CAD Course, the tricopter emerged as a testament to the program’s commitment to pushing boundaries. The initial design, crafted by Project Faction, laid the foundation for becoming a symbol of innovation within the UDT Mechanical Design Program. Unique Shell Design:The tricopter’s defining feature is its distinctive shell design, capturing attention with its unconventional aesthetic. This unique characteristic adds a touch of creativity and serves as a representation of the program’s dedication to fostering innovative design solutions. Carbon Fiber Arms and 3D-Printed Chassis:Crafted with long, slender arms made from carbon fiber, the tricopter’s structural integrity is enhanced while maintaining a lightweight profile. The entire chassis or frame is fully 3D printed, showcasing the program’s commitment to embracing modern manufacturing techniques. A Glimpse into the Future:The 2019 tricopter project serves as a precursor to the future of design education within the UDT Mechanical Design Program. By combining traditional principles with cutting-edge technologies like 3D printing, students are encouraged to think beyond conventional boundaries and pioneer new realms of design. Technical Specifications:The tricopter is equipped with a Pixhawk flight controller, 30A SimonK ESCs, and A2212 motors, all contributing to its stability and precise aerial maneuvers. With long, slender carbon fiber arms and a fully 3D-printed chassis, this tricopter exemplifies the program’s dedication to merging innovative design and advanced manufacturing techniques. Conclusion:As we reflect on the first tricopter born from the UDT CAD Course in 2019, now an integral part of the UDT Mechanical Design Program, we see more than a mere drone. It represents the spirit of innovation, the fusion of traditional and modern design principles, and a commitment to pushing the limits of what’s possible. The journey has just begun, and with each new project, the UDT Mechanical Design Program continues to shape the future of design education. https://projectfaction.com/wp-content/uploads/2021/12/tricopter-first.mp4